Design & Engineering

Precision Manufacturing

Safety Standards

Space Optimization

Quality Assurance

Customizable Options

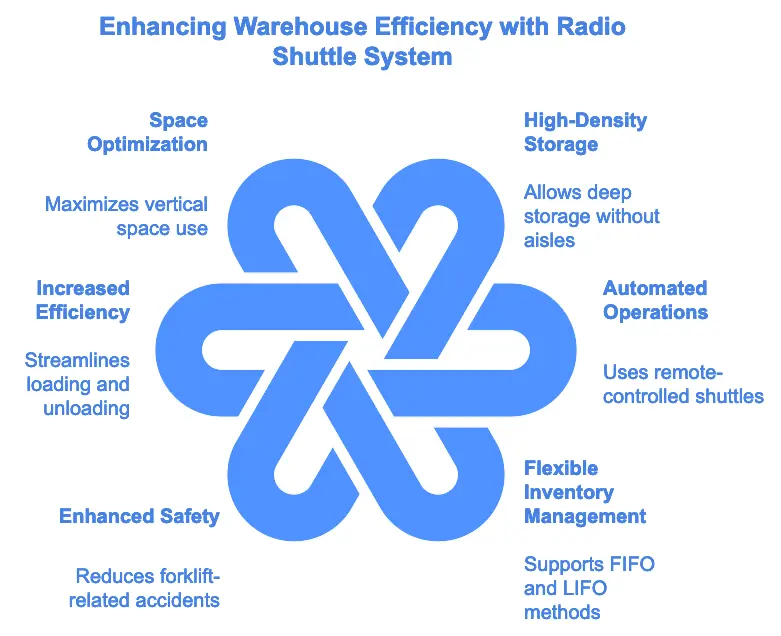

Key Features

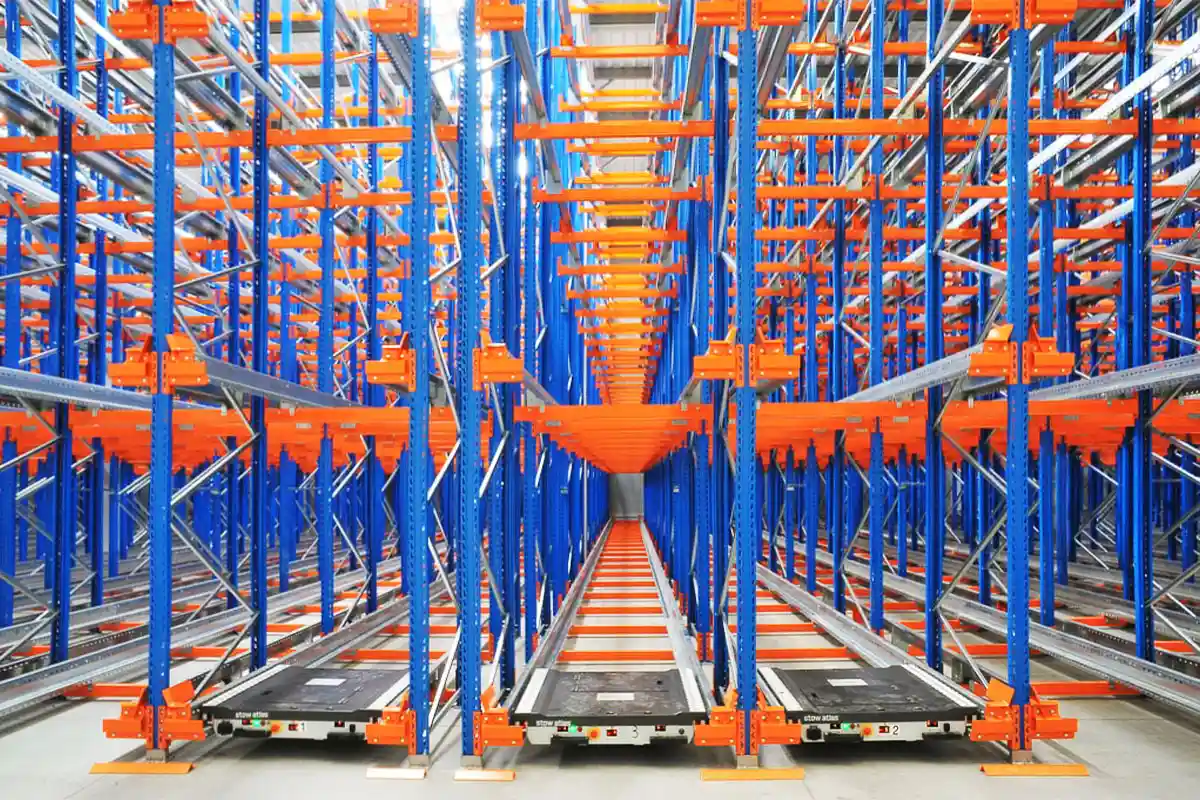

- High-Density Storage: The Radio Shuttle System allows for deep storage without the need for aisles, enabling more pallets to be stored in a smaller footprint. This is particularly beneficial for high-volume operations.

- Automated Operations: With remote-controlled shuttles, the system automates the movement of pallets, minimizing manual handling and reducing labor costs. It can handle various pallet sizes and weights, accommodating loads up to 1,500 kg.

- Flexible Inventory Management: The system supports both FIFO (First-In-First-Out) and LIFO (Last-In-First-Out) inventory management methods, ensuring optimal stock rotation and reducing the risk of spoilage.

- Enhanced Safety: By eliminating the need for forklifts to enter the racking structure, the Radio Shuttle System reduces the risk of accidents and product damage, creating a safer working environment.

Benefits

- Increased Efficiency: The automation of pallet handling streamlines operations, allowing for faster loading and unloading times. This efficiency translates into significant time savings for warehouse operations.

- Space Optimization: The design of the system maximizes vertical space utilization, making it ideal for facilities with limited floor space.

- Real-Time Inventory Tracking: Many systems integrate with warehouse management software (WMS), providing real-time visibility into stock levels and improving inventory management.

Applications

The Radio Shuttle Racking System is suitable for a variety of industries, including:

- Food and beverage distribution

- Cold storage facilities

- E-commerce fulfillment centers