In the fast-paced world of warehousing and logistics, efficient use of space and the optimal organization of goods are paramount. When it comes to achieving these goals, two popular solutions stand out: Pallet Live Storage and Traditional Racking. These systems offer distinct approaches to storing and accessing inventory within a warehouse environment. In this article, we’ll dive deep into these systems, exploring their features, benefits, and suitability for various scenarios.

Understanding Pallet Live Storage

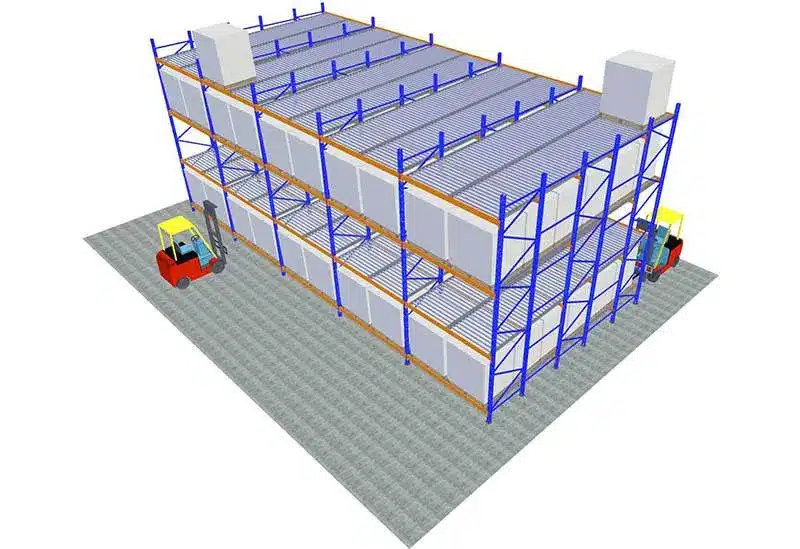

Pallet Live Storage, often referred to as a live pallet racking system, is a dynamic approach to warehouse storage. The system employs gravity rollers or conveyors to create a flow-like environment for pallets. This ensures that the first pallet loaded is also the first to be retrieved—a concept known as First-In, First-Out (FIFO). The design of this system minimizes the need for manual intervention when moving inventory, and optimizing stock rotation.

Benefits of Pallet Live Storage

- Maximized pallet space: The utilization of gravity rollers allows for a dense arrangement of pallets, making the most of the available warehouse pallet space.

- Efficient stock rotation: FIFO management reduces the risk of product obsolescence by ensuring older stock is used before newer additions.

- Streamlined goods handling: Pallets glide forward for easy access, reducing the time and effort required for retrieval.

- Supports FIFO management: Pallet Live Storage is designed to follow the FIFO principle, ensuring that older inventory is used before newer additions.

Drawbacks of Pallet Live Storage

- Higher initial investment: The installation of gravity rollers or conveyors requires a greater upfront investment compared to static racking.

- Complex maintenance: The moving components in this system may demand more frequent maintenance, potentially leading to operational downtime.

Traditional Racking

On the other side of the spectrum, we have the tried-and-true Traditional Racking system. In this approach, pallets are manually placed and retrieved from fixed shelves, making it well-suited for items with less frequent turnover.

Advantages of Traditional Racking

- Cost-effective: Traditional racking involves lower initial costs and is simpler to set up, making it an economical choice for certain businesses.

- Simple design: The straightforward nature of static racking simplifies maintenance and reduces the likelihood of technical issues.

- Ideal for large items: Bulky or heavy items find their place in static racks, which offer stable support for items of varying sizes.

- Does not require FIFO management: Traditional Racking does not require FIFO management, which can be a benefit for businesses that do not need to strictly adhere to this principle.

Limitations of Traditional Racking

- Limited stock rotation: FIFO management is not inherent to this system, potentially leading to inventory stagnation.

- Lower storage density: Static racking occupies more floor space, resulting in lower storage density compared to pallet live storage.

Choosing the Right System for Your Warehouse

The choice between Pallet Live Storage and Traditional Racking hinges on the nature of your inventory and operational requirements. Here are a few considerations to guide your decision:

- Inventory turnover: High turnover favors Pallet Live Storage, while slower-moving items may work well with Traditional Racking.

- Item size: Bulky or irregularly shaped items lean toward Traditional Racking’s sturdy design.

- Initial budget: Pallet Live Storage requires a greater investment initially, while Traditional Racking offers a cost-effective setup.

- Maintenance capacity: Static Racking is simpler to maintain, while Pallet Live Storage demands more intricate upkeep.

Conclusion

In the ongoing debate of Pallet Live Storage vs. Traditional Racking, there is no one-size-fits-all answer. Each system brings its unique advantages and limitations to the warehouse landscape. The decision ultimately boils down to your specific business needs, inventory characteristics, and long-term goals. By aligning your choice with your operational requirements, you can unlock the potential of your warehouse space, ensuring efficient stock management and optimized storage.

FAQs

- Q: What is Pallet Live Storage?

- Pallet Live Storage is a dynamic warehousing approach that employs gravity rollers for efficient stock rotation and storage.

- Q: Which system is more cost-effective?

- Generally, Traditional Racking is considered more budget-friendly in terms of initial investment.

- Q: How does Pallet Live Storage optimize stock rotation?

- Pallet Live Storage follows the “First-In, First-Out” (FIFO) principle, ensuring that older inventory is used before newer additions.