Introduction

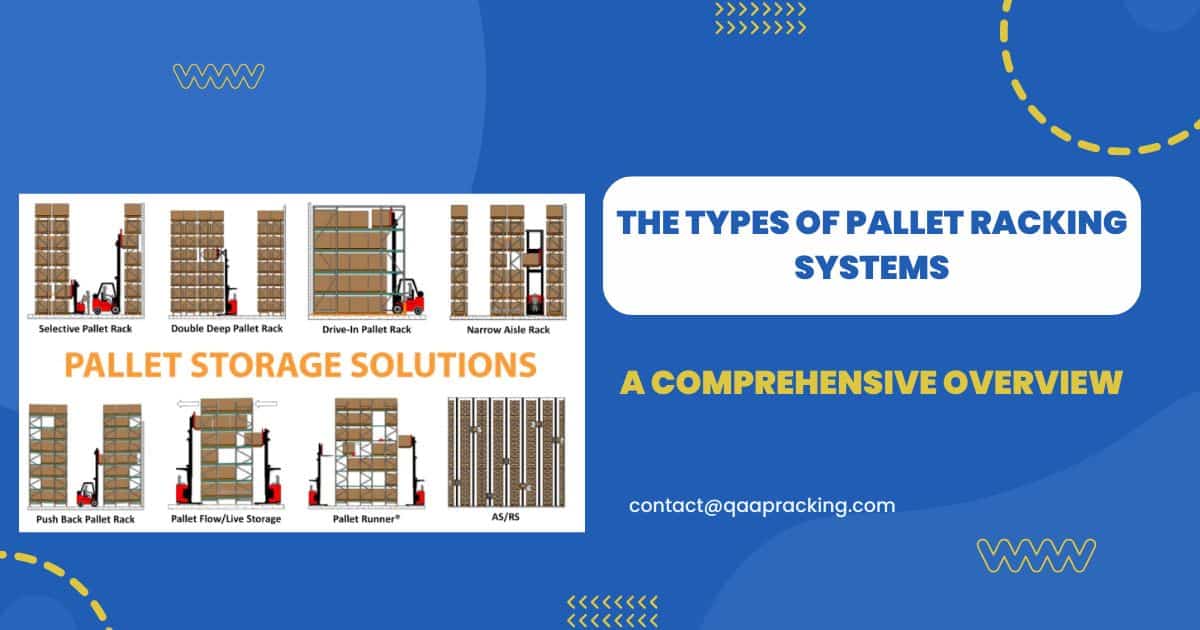

When it comes to efficient warehouse management, selecting the right pallet racking system is crucial. Different types of pallet racking systems can significantly impact your storage capabilities and operational efficiency. In this post, we’ll explore the various types of pallet racking systems available, their features, and how to choose the right one for your business needs.

1. Selective Pallet Racking

Selective pallet racking is the most common type used in warehouses. It allows direct access to each pallet, making it easy to pick and store items. This system is ideal for warehouses with a wide variety of products and fast turnover rates.

- Benefits:

- High accessibility to all stored pallets.

- Versatile and easy to adjust.

- Suitable for various pallet sizes.

2. Drive-In Pallet Racking

Drive-in racking systems are designed for high-density storage. Forklifts can drive directly into the racking structure to load and unload pallets, maximizing storage space by eliminating aisles. This system is best for products with low turnover rates.

- Benefits:

- Increased storage density.

- Efficient use of space.

- Reduced aisle space.

3. Push Back Racking

Push back racking systems utilize inclined tracks to store pallets. When a new pallet is loaded, it pushes the existing pallets back. This system allows for a first-in, last-out (FILO) inventory management system.

- Benefits:

- High-density storage with easy access.

- Efficient inventory turnover.

- Reduces handling times.

4. Flow Racking

Flow racking systems operate on a first-in, first-out (FIFO) basis. They use rollers to allow pallets to slide down into position, making it ideal for perishable goods. This system is highly effective for managing stock rotation.

- Benefits:

- Ensures product freshness and reduces spoilage.

- High-density storage.

- Streamlined picking processes.

5. Mobile Pallet Racking

Mobile racking systems are mounted on wheeled bases, allowing them to move. This flexibility enables you to create aisles only when needed, maximizing space in your warehouse.

- Benefits:

- Optimizes storage capacity.

- Adaptable to changing inventory needs.

- Enhances accessibility.

6. Cantilever Racking

Cantilever racking is specifically designed for storing long or bulky items, such as lumber, pipes, or furniture. This system features arms that extend from a vertical structure, allowing for easy access to items.

- Benefits:

- Ideal for unconventional shapes and sizes.

- Maximizes vertical space.

- Simple design for easy loading and unloading.

Conclusion

Choosing the right type of pallet racking system is essential for maximizing your warehouse’s efficiency. Understanding the differences between selective, drive-in, push back, flow, mobile, and cantilever racking systems can help you make an informed decision that aligns with your storage needs.

If you’re considering upgrading your warehouse storage solutions, reach out for tailored advice on the best pallet racking systems for your business.

Call to Action

If you found this article helpful, please share it with your colleagues and check out our other posts on warehouse management tips. For tailored solutions and quotes on pallet racking systems, feel free to contact us.